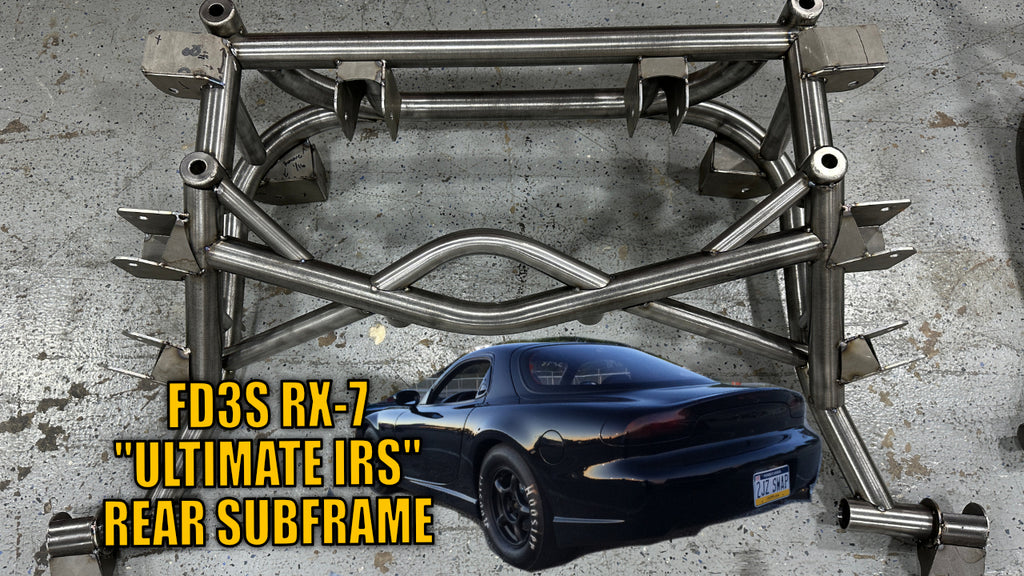

Our first prototype subframe is complete and ready to show it to the world.

This is a complete bolt-in rear tubular subframe for the 1993-1995 Mazda RX-7 (FD3S) chassis. This is 100% chromoly, so it is not only lightweight but extremely strong. The bare stock stamped steel subframe is around 30 lbs, this bare subframe is 10 lbs heavier, weighing it at only 40 lbs. This small 10lb weight gain is a small price to pay for the increase in chassis stability and strength. The stock subframes have been known to tear, especially when upgrading to an 8.8 rear end and welding in bars.

The subframe is available bare, powdercoated satin black, or powdercoated a custom color of your choice.

This will make the entire IRS suspension more rigid. Removing the play and twist from IRS suspension systems is key in making it work better. It weighs only 10 lbs more than the stock subframe and adds a ton of strength and rigidity to the chassis. It's like adding a roll cage to the rear of the car.

The subframe cradle uses all the factory mounting locations to the chassis and stock locations for all suspension arms. This is also designed to work with the factory spindle. You can use all factory control arms other than the lower control arm (that has the eccentric bolt) - this subframe does not use the eccentric bolts, so you will need to have an adjustable arm there to adjust camber.

For the differential, it also uses the stock mounting locations, so you can use stock differential or an aftermarket rear end kit like my 8.8" or 9" kit. For example, you can see my FD3S 9" kit in the pictures.

For guys who already have an 8.8 rear end, this subframe will work with existing Ronin 8.8 customers as well, so if you already have the Ronin kit, you can direct swap out this subframe for your stock modified one. You can then sell your modded 8.8 subframe and recoup some of the costs.

This is something I have wanted to build for quite some time, so seeing John bring this to life is really awesome to see.

I am going to offer *** 12 PRE-ORDER SPOTS *** and they are available now.

It will be available to work with the stock rear, ford 8.8" rear, and ford 9" rear. More details are on the product page here --> FD3S Ultimate IRS Rear Subframe

Here is a video i made showing the subframe in the car and also a little overview of my FD3S collection as well.

Continue reading